Reducing the Cost of Installing Constant Current LED Drivers

If you are working on a lighting design or installation that involves the use of multiple constant current LED drivers, there could be a far more cost-effective method of powering the LEDs using DC to DC LED drivers.

To demonstrate this, we will work on an example installation that involves 10 LED luminaires, each requiring a 350mA LED driver with a 15-28VDC forward voltage range.

The immediate solution that may come to mind is to use 10 constant current LED drivers to take the incoming 240VAC power and supply the DC power at the correct current.

Instead, it would be cheaper to buy one constant voltage LED driver and use this to supply the DC power to 10 DC to DC LED drivers, which will regulate the constant current supplied to each of the luminaires.

Selecting the Correct DC to DC LED Driver

For optimum performance, the DC to DC LED drivers should have the exact current output required to power the LED luminaires.

If you can’t find one with the exact current rating, you can go a little lower if needed, but don’t go higher. You may overdrive the LEDs and cause them to burn out. In most cases if you use a lower current LED driver, the luminaires will still work well, even though may not be quite as bright as they could be.

The LED driver must have a forward voltage range that can accommodate the range required by the LED luminaires. In our example the luminaires require 15-28VDC.

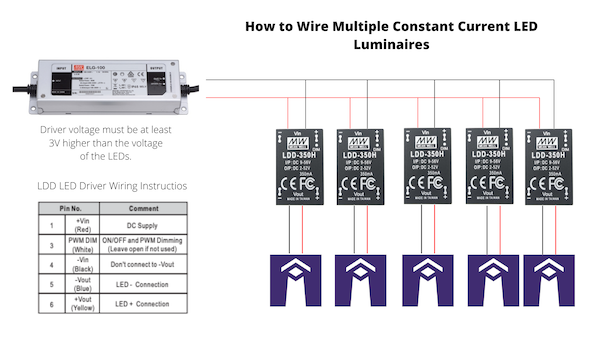

Therefore, the MEAN WELL LDD-350HW is a suitable option. Its 2-52VDC forward range of the LDD-350HWs is more than adequate and it delivers the required constant current of 350mA.

10 LDD-350HWs are required for this installation. One for each LED driver.

Selecting a Suitable Constant Voltage LED Driver

Only one constant voltage LED driver is required. This will take the incoming 240VAC mains and supply a DC voltage to each of the LDD-350HW DC to DC LED drivers.

First, we need to calculate the required output voltage of the LED driver.

The LDD-350HWs need an input voltage 3V higher than the output to make them work. Use the top end of the forward voltage range required by the LEDs to do your calculations. In our scenario this is 28V LEDs, so a LED driver with a 36V input is a good choice. 24V would be too low and 36V is the next voltage up in the MEAN WELL range.

Next, we need to calculate the required power output of the LED driver.

To calculate the size of constant voltage LED driver required, you first work out the maximum power each LED luminaire could draw.

This is done by multiplying the output current by the top of the forward voltage range. So, in our example this would be 350mA (0.35A) x 28V = 9.8W. You then multiply this maximum power rating by the number of luminaires: 9.8W x 10 = 98W.

Now add another few Watts to allow yourself some headroom to prevent the power supply from being accidentally overloaded.

So, in our scenario above we need a LED driver with an output of at least 100 Watts, such as the MEAN WELL ELG-100-36AB.

One thing to watch out for is the minimum operating voltage of the driver supplying the input voltage. A 36V driver will operate down to 18V before it senses an overload and starts to “hiccup”. This limits the minimum usable voltage with this type of installation.

Therefore, if your LEDs only ran at 10V, the power supply will try to provide power at (10+3) Volts and will sense an overload and start to “hiccup”.

The below wiring diagram shows how an ELG-100-36AB and the 10 LDD-350HWs should be installed:

Using this example, we calculate that your hardware cost would be approximately 50% cheaper if you had used the single ELG-100-36AB to power 10 LDD-350HWs instead of buying 10 x 350mA 240VAC constant current LED drivers.

If you would like assistance in selecting a suitable constant current LED driver for your installation, then please contact ADM.

Is this Information Useful?

If so, why not share it with your peers and colleagues. Simply click on the blue LinkedIn share icon below.